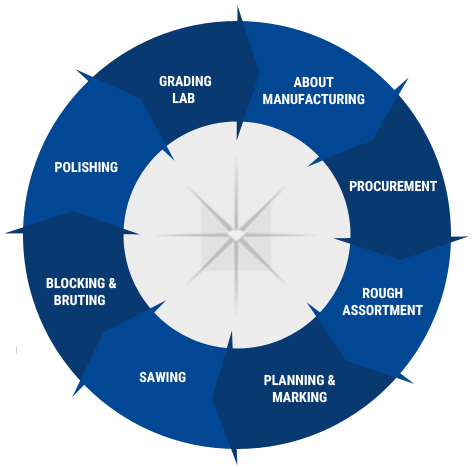

About Manufacturing

Equipped with state-of-the-art technology, the production unit in Surat manufactures high quality polished diamonds and also ensures the evenness of supply. To have concentrated controlling efforts in production, we have a new unit spread across in 6800 sq. yards offering more than 1.75 lakh sq. ft. of working space and employees over 2000 artisans.

At J.B. And Brothers, we have highly skilled artisans who use advanced technology to deliver optimum results. Our manufacturing process starts from acquiring the raw materials and ends with perfectly graded polished stones.

Procurement of Rough

Diamond

We procure rough diamonds from leading diamond suppliers like De Beers, Angola, Dominion, South African, Chikapa, Katuka, Russian amongst others

Rough Assortment

| Stones | Unbroken crystal with regular formation. |

| Shapes | Unbroken crystal with less regularity. |

| Cleavages | Broken &/or irregular shaped |

| Macles | Triangular shape with twinned crystals |

| Flat | Diamond Crystal of irregular shape having flat parallel sides looks like pieces of broken glass. |

Brilliant cut gems can be made except from Flat. Grading is also done as per heaviness of inclusions, color and size

Planning & Marking

Rough stones are planned and marked as per the shape and size of rough, inclusion's position, density and current market situation of various shapes.

| Brilliant Cut (Round) | Marquise | Pear |

| Princess | Oval | Emerald |

| Square Emerald | Radiant | Square Radiant |

| Heart | Triangle | Trilliant |

| Cushion | Square Brilliant | Rectangle Brilliant |

| Fancy Cut |

Inclusion's position, density and current market situation of various shapes.

Planning is done using the two technologies, Sarine Galaxy and Octonus IG whereby we get much more accurate projection of inclusions which assists us while doing the planning of the stones.

Sawing

Sawing Details:-- Sawing is the separation of a piece of diamond rough into separate pieces, to be finished as individual diamonds after planning the stone

In Sawing we use Blade or Laser to cut the rough diamond into separate pieces. This may be used to remove extra portions of the diamond as well

Blade Sawing :-- Blade Sawing is the technology where we cut the diamonds using highly precise diamond powder coated Blades. The advantage is low cutting loss

Laser Sawing:-- Laser Sawing is using highly precise cutting technology with more atomization and making things more precise and accurate

Blocking & Bruting

Raw diamonds are sent for blocking or bruting after the cleaving / sawing process. Blocking/bruting gives shape to raw diamonds. Rounding the corners of a diamond is known as bruting. In our manufacturing procedure, we use the latest technology for bruting- Auto Brutter and Auto laser Brutter machine.

Polishing

After bruting, diamond are sent for polishing. At this stage, our experts reassess diamonds for any chance of clarity improvement as per their size. This is the last process of manufacturing in which artisans take care of the diamond's symmetry, crown angle, polishing lines and various other factors.

Every process is inclusive of :-

- Use of modern equipment like helium machine to get excellent symmetry.

- Use of smart-I Finger printing machine for polished diamond registration.

- Rough analyser to increase precision and management control.

- Logical flow of inventory to ensure smooth functioning of factories.

- Substantial decrease in the need to re-cut polished diamond to near zero.

- Effective handling of diamonds with air bubbles.

- Step by step polishing of diamond to save lustre.

Grading Lab

We educate our customers about our minute grading system on various factors. Due to this we can take full advantage to promote & increase our business through E-Commerce. We manufacture 0.18 cts to 20 cts plus sizes in Round, Princess, Marquise, Pear, Oval, Square Emerald, Emerald, Square Radiant, Radiant, Heart, Cushion etc. Grading is carried out according to rigorous criteria mapping with Labs of International repute & various other minute factors developed by our well-equipped Research Laboratory Team. In our laboratory, we have taken care of each C's in depth so that you can visualize the stone in front of your eyes. Our grading is based on GIA system so there is higher chance of upward color certification in other Lab. To narrow down the price band we give (+) color & (+/-) clarity grading.